Cheap, tough and green: why aren't more buildings made of rammed earth?

It’s fair to say that rammed earth, as a construction technique, has stood the test of time. It has been used to create buildings around the world whose beauty and robustness are still visible today, like the Alhambra in Spain and the Great Wall of China, both built more than 1,000 years ago.

Traditional rammed earth is made of a mix of clay-rich soil, water and a natural stabiliser such as animal urine, animal blood, plant fibres or bitumen. It is then compacted inside temporary formworks that are removed after the mix has dried and hardened. The resulting structure can withstand compressive forces of up to 2.5 megapascals (around 10% of the average compressive strength of modern bricks).

The walls can be reinforced using embedded timber beams or bamboo grids, and of course they need some architectural features to protect them from the rain and wind. Historical examples of buildings made of traditional rammed earth can be found in South America, China, India, the Middle East and North Africa.

In Europe, especially in France, Britain and Germany, traditional rammed earth is enjoying a resurgence, and several modern buildings have been constructed using the technique, such as the three-storey rammed earth home shown below, built in 2008 in Austria.

In the past 30 years a new version of rammed earth has appeared and gained popularity in certain parts of the world, such as Australia, California and Canada. Called cement-stabilised rammed earth (CSRE), it consists of a mix of low-clay soil, water and cement. Like traditional rammed earth, this mixture is compacted inside temporary formworks and left to dry.

But it is an order of magnitude stronger, withstanding compression forces up to 40 megapascals, giving it similar strength and durability to concrete. This means that walls do not need special protection from rain and wind because they are strong and durable, especially if reinforced with steel.

Sustainable building blocks

Both traditional rammed earth and CSRE have several characteristics that make them an attractive choice of building material. The main ingredient is soil, which is cheap (if not free). In remote areas, building with local soil means significantly reducing the costs of transporting construction materials to the site.

The building technique is very straightforward. In general, only one experienced builder is required on site to instruct labour force about how to construct the formwork and mix the materials. The rest of the work can be done by untrained or unskilled people from the local community, creating jobs and reducing the costs of transporting and accommodating workers from elsewhere.

Although rammed earth does not have very good insulating properties, the walls are very thick (typically 250-800 mm), meaning that rammed earth buildings can easily produce comfortable indoor conditions in hot and arid places. Rammed earth walls breathe, hence they can regulate the indoor relative humidity, making it suitable for people with respiratory problems.

And finally, the final texture of rammed earth walls is unique and beautiful, so they typically do not need any plaster or render.

Ramming home the message

There are currently several projects around the world that aim to promote rammed earth as a sustainable and cost-effective construction technique.

My colleagues and I are working with the WA Department of Housing to investigate the use of CSRE in remote Indigenous communities. Gaining the trust of the Indigenous population has been so far the most difficult aspect of the project.

Meanwhile, in the United States, Colorado University is starting a similar project to look at the possibility of building rammed earth homes on Native American reserves.

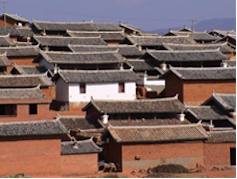

Most impressively of all, China’s Xi’an University of Architecture and Technology has developed a project to help rural communities build new houses using both traditional and modern rammed earth. The scheme has successfully helped the local population to create entire new villages built with rammed earth.

But rammed earth is not only applied in affordable housing projects. Strangely enough, the other most common application is in expensive residential buildings designed by eccentric architects for wealthy and environmentally concerned clients. These houses usually end up in and and design magazines and are considered real pieces of art.

So, why isn’t everyone using it?

Rammed earth has been used for centuries, but today its use is limited to specialised projects like the ones described above. Why is it not extensively used around the world, for ordinary buildings like offices and houses?

One of the major reasons is likely to be a lack of knowledge. Although rammed earth itself is old, our research is quite a new field compared with other more traditional construction materials like concrete, steel, masonry and timber. Unfortunately, a lack of research means a lack of understanding of the material and its structural properties.

Another obstacle is regulation, or a lack of it. In Australia, as in most countries, there is no building code for rammed earth buildings. The prospect of working with an unregulated construction technique would discourage many engineers and architects.

The good news is that the interest in environmentally friendly and affordable houses has never been bigger. Researchers from different backgrounds (engineering, materials science, architecture, chemistry, and more) are beginning to investigate the different properties of rammed earth with the aim of promoting this construction technique.

While it might not be as grand as the Alhambra, the chances of finding yourself inside a rammed earth building in the years to come are growing.![]()

Daniela Ciancio, Senior Lecturer, Civil, Environmental and Mining Engineering, University of Western Australia

This article is republished from The Conversation under a Creative Commons license. Read the original article.