Concrete processing to the point

Precise control of the processing time thanks to the new superplasticizer series

Concrete is a material whose properties must meet certain framework conditions during processing. Especially in the production of precast concrete parts, the hardening times of the fresh concrete have a significant influence on the entire process. Ha-Be Betonchemie starts here with a specially developed problem solution for the precise control of the processing times. The PANTARHIT® PC83X superplasticizer series enables users to precisely plan processing times according to individual needs - and thus also increases the efficiency and effectiveness of the entire concrete processing company.

The processing of concrete poses a number of challenges: the material hardens too quickly or it takes too long to set. Processes are slowed down, there is idling and the product can show quality defects, in case of doubt it can become unusable. As an established company with well-founded know-how in concrete chemistry, Ha-Be knows these challenges and has developed a targeted solution: the new superplasticizer series PANTARHIT® PC83X.

PANTARHIT® PC83X enables fine tuning in processing

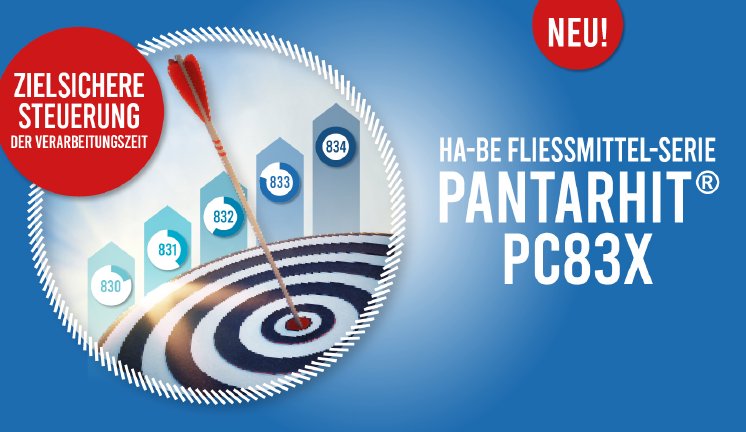

The new series of PANTARHIT® PC83X superplasticizers consists of the products PC830, PC831, PC832, PC833 and PC834, each of which is designed to maintain a specific, targeted consistency of the concrete according to different requirements. Depending on the task, ambient temperature and individual work planning, the PC83X series offers users a type of modular system for concrete production.

Should e.g. For example, when the outside temperature is hot, a longer processing time can be brought about, so users can go up the product line. PANTARHIT® PC834 (FM) is therefore the superplasticizer with the strongest consistency retention, while PANTARHIT® PC830 (FM) ensures the fastest strength development. The gradation within the PC83X series allows a veritable fine-tuning of the consistency maintenance and thus brings maximum efficiency and effectiveness into production.

Use of superplasticizer for efficient production processes

The PANTARHIT® PC83X products achieve high early strengths in the concrete even at low temperatures and without additional heat treatment. Processing cycles can be shortened and significantly faster cycle times can be achieved through faster reuse of molds and formwork. In addition to cost savings and increased effectiveness, the early strength contributes to a better energy balance and increased sustainability.

Last but not least, production companies achieve an improvement in product quality with PANTARHIT® PC83X. The concrete is optimally compacted through the use of the new superplasticizer technology. In this way, concrete with a closed, low-pore surface and a homogeneous appearance can be produced, which not only has a positive effect on the visual appearance, but also increases the quality and durability of the building material.

The processing of concrete poses a number of challenges: the material hardens too quickly or it takes too long to set. Processes are slowed down, there is idling and the product can show quality defects, in case of doubt it can become unusable. As an established company with well-founded know-how in concrete chemistry, Ha-Be knows these challenges and has developed a targeted solution: the new superplasticizer series PANTARHIT® PC83X.

PANTARHIT® PC83X enables fine tuning in processing

The new series of PANTARHIT® PC83X superplasticizers consists of the products PC830, PC831, PC832, PC833 and PC834, each of which is designed to maintain a specific, targeted consistency of the concrete according to different requirements. Depending on the task, ambient temperature and individual work planning, the PC83X series offers users a type of modular system for concrete production.

Should e.g. For example, when the outside temperature is hot, a longer processing time can be brought about, so users can go up the product line. PANTARHIT® PC834 (FM) is therefore the superplasticizer with the strongest consistency retention, while PANTARHIT® PC830 (FM) ensures the fastest strength development. The gradation within the PC83X series allows a veritable fine-tuning of the consistency maintenance and thus brings maximum efficiency and effectiveness into production.

Use of superplasticizer for efficient production processes

The PANTARHIT® PC83X products achieve high early strengths in the concrete even at low temperatures and without additional heat treatment. Processing cycles can be shortened and significantly faster cycle times can be achieved through faster reuse of molds and formwork. In addition to cost savings and increased effectiveness, the early strength contributes to a better energy balance and increased sustainability.

Last but not least, production companies achieve an improvement in product quality with PANTARHIT® PC83X. The concrete is optimally compacted through the use of the new superplasticizer technology. In this way, concrete with a closed, low-pore surface and a homogeneous appearance can be produced, which not only has a positive effect on the visual appearance, but also increases the quality and durability of the building material.