Qatar Foundation Stadium for the 2022 FIFA World Cup: FineHVAC Case Study

FineHVAC has been used for the design of several stadiums and athletic facilities, one of those being the Athens Olympic stadium two decades ago. Recently it was used for the dimensioning of the HVAC installations for the Qatar Foundation Stadium, a host venue for the upcoming 2022 FIFA World Cup™ and one of the principal sports complexes in Qatar.The HVAC case study was carried out by GKA engineers on behalf of SALFO & Associates SA.

The Project

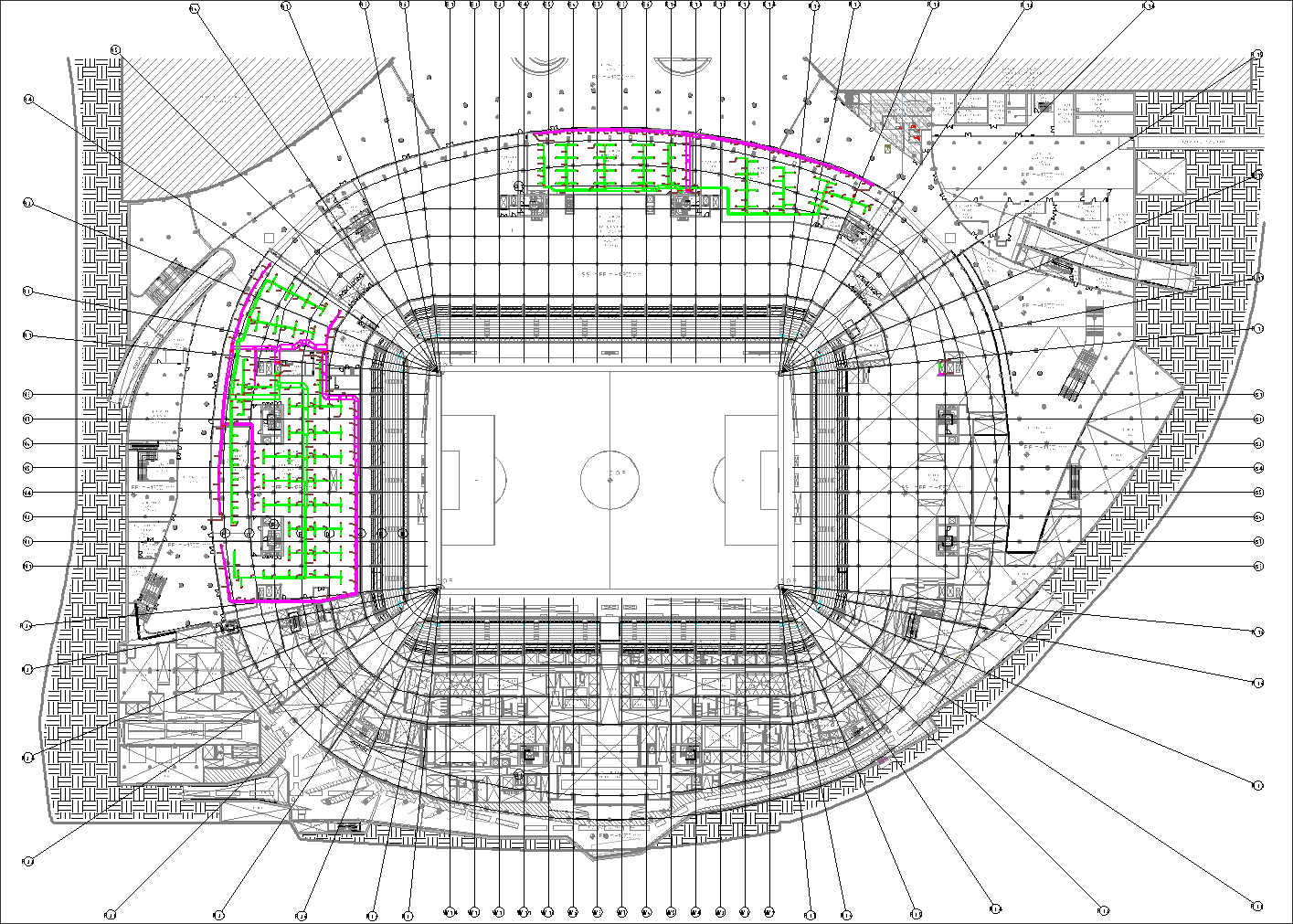

Qatar Foundation Stadium is a sport complex located on the west side of the Southern campus of the Education City complex in Doha, and it is envisioned as a major sporting venue in Qatar as well as the University campus itself. HVAC design, and more specifically, the piping and air-duct installations serving the free space under the stands of the Qatar Foundation Stadium were designed by FineHVAC software.

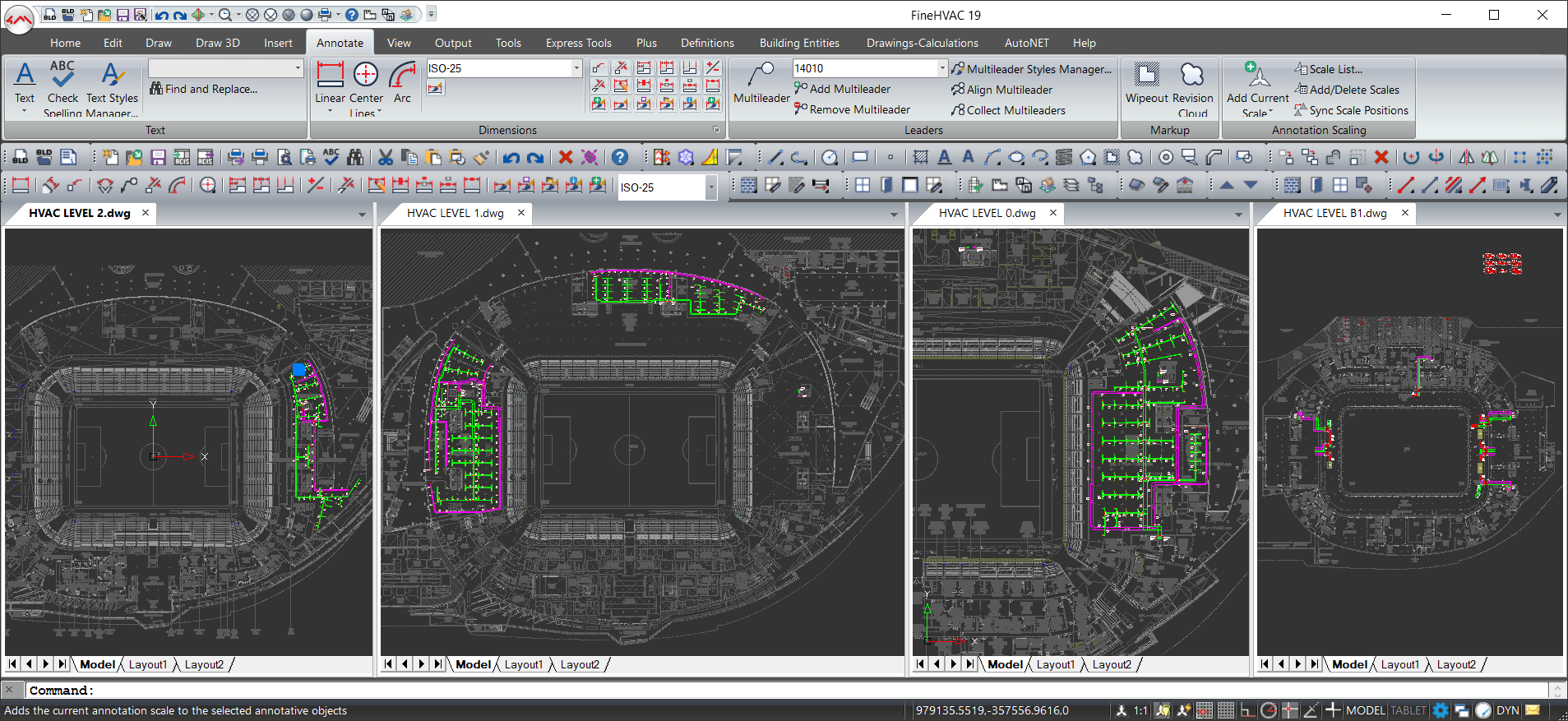

In the project, the total surface of the airconditioned area is over 55.000 m2, structured in four levels and further divided in separate spaces, aiming at housing the main support facilities (catering, management and administration, back of house stores, loading bays, etc.) for the 2022 FIFA World Cup™. Among other considerations, the design had to take into account the fact that most of the existing spaces were (and are) planned to be reconstructed into a mall complex as soon as the World Cup event is over.

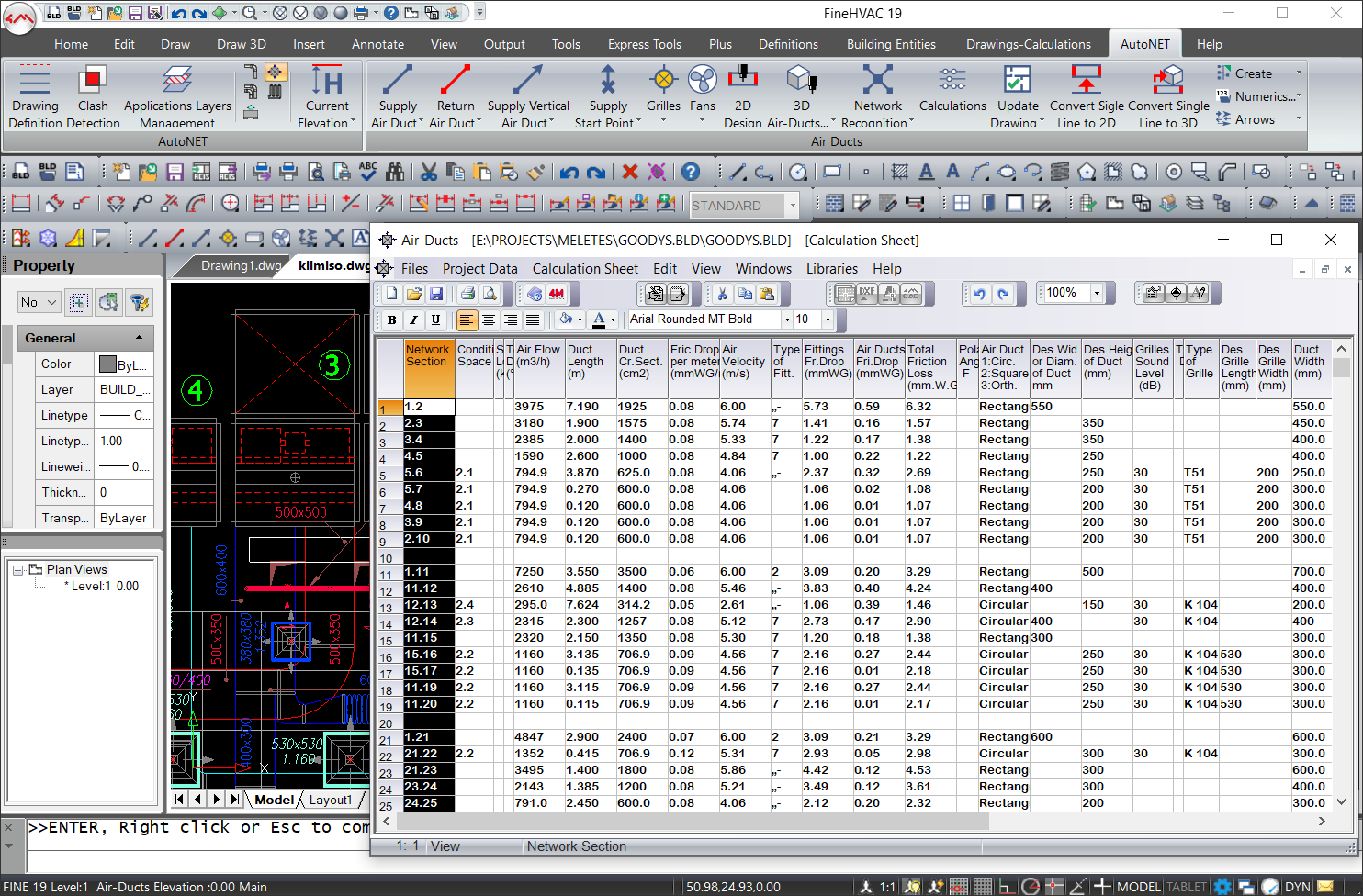

Regarding the air ducting network itself, it is comprised of over 1000 nodes and 1300 pipe segments, incorporating 400 end segments with air-grills. Putting this in context of the capabilities of the software, FineHVAC has a total capacity of 4.500 separate nodes in a single project, which means that the program can handle up to three times the size of this project, in a single project file. FineHVAC provides the option to split up a project into pieces, as parts of the entire project, which practically means that there are no limits on the scale of the project it can handle.

Following the case study results, the total air-flow capacity of the ventilators is 20.600 l/s, a value which is distributed by level and space as shown at the following table.

| Sections | 1st Section | 2nd Section | ||

| Levels | Supply l/s | Return l/s | Supply l/s | Return l/s |

| 0 | 8500 | 8500 | - | - |

| 1 | 7100 | 7100 | 3420 | 3300 |

| 2 | 5000 | 5000 | - | - |

Advantages of FineHVAC Adoption

The selection of FineHVAC software for this specific project was due to several reasons:

Network Modeling

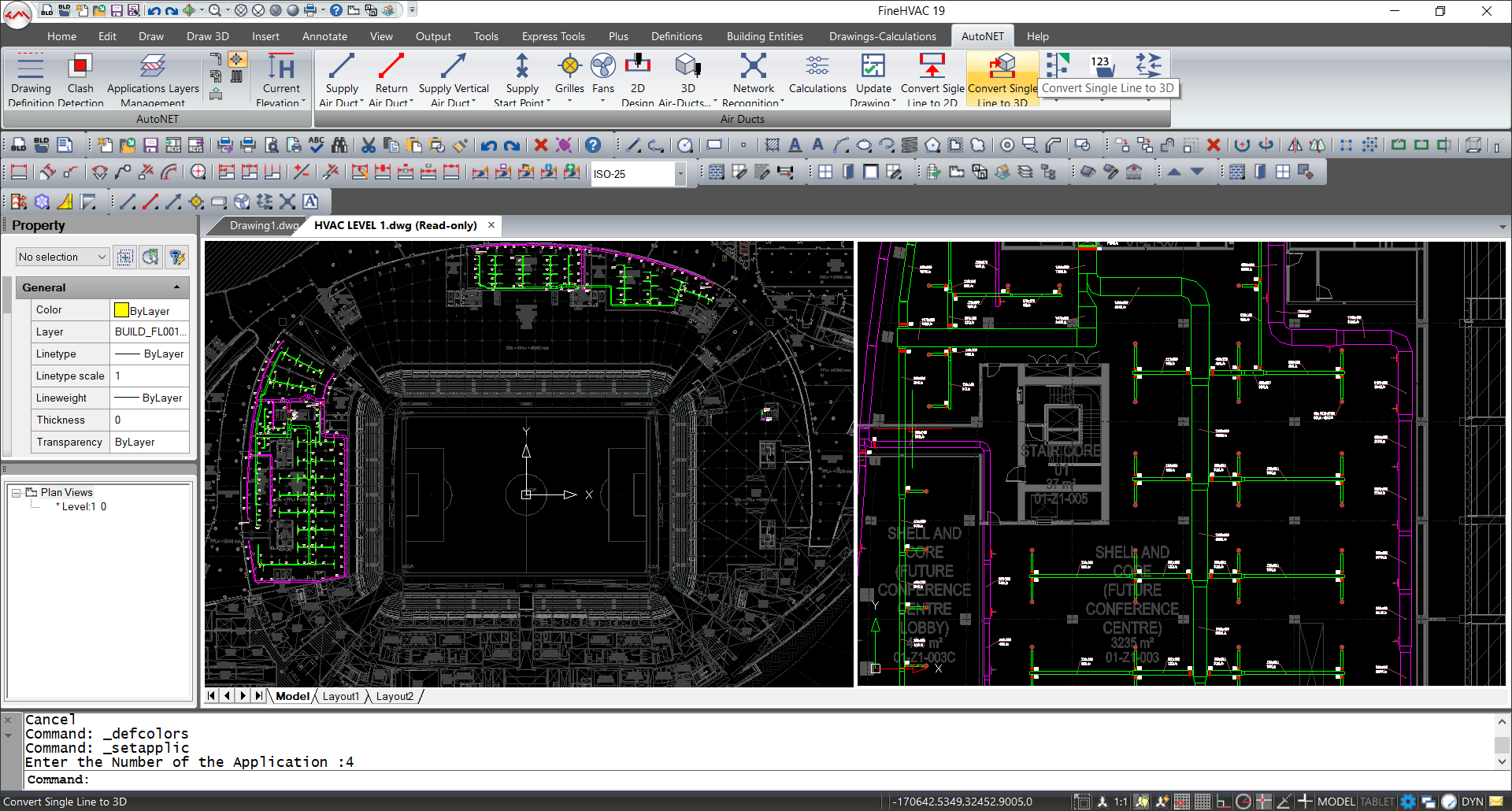

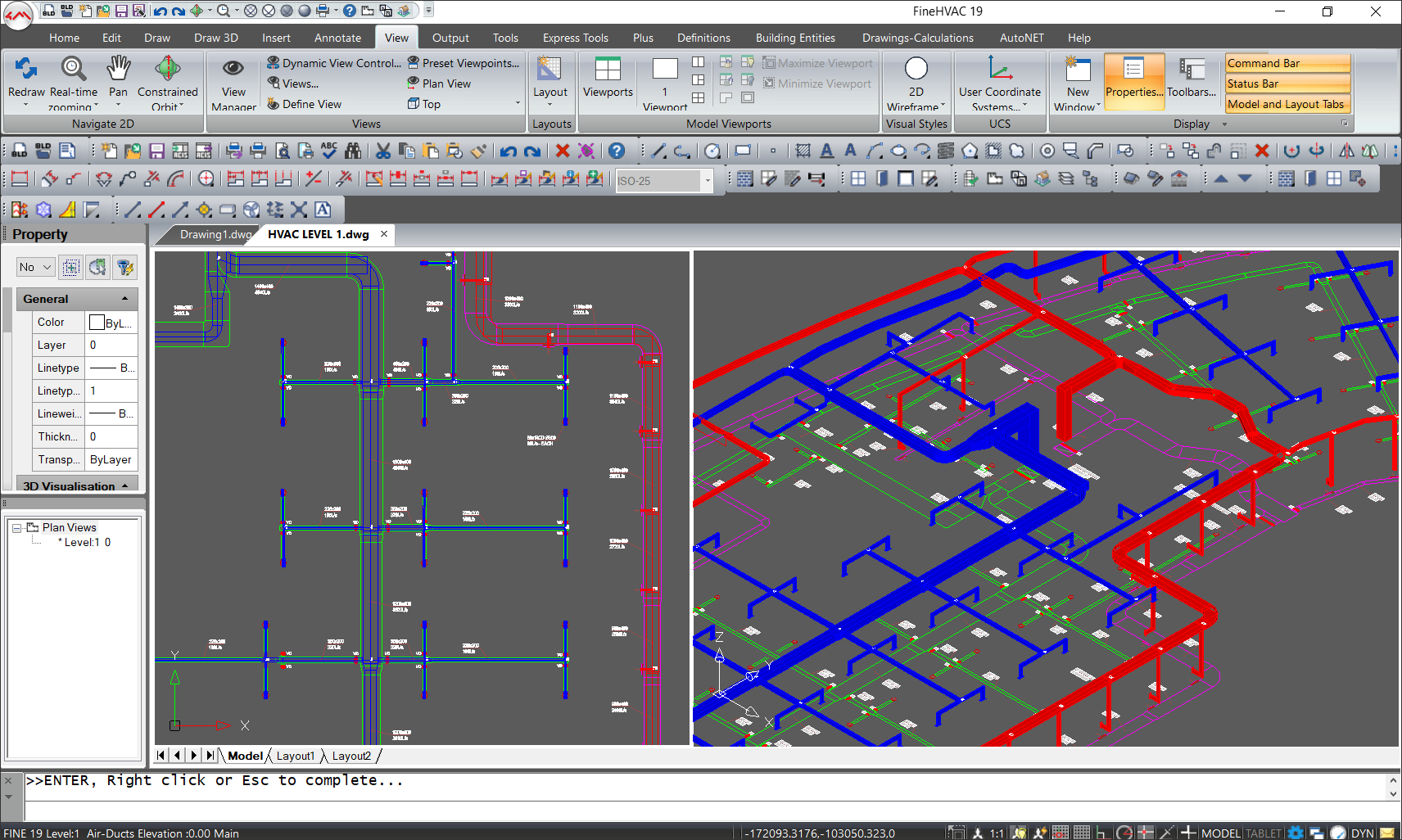

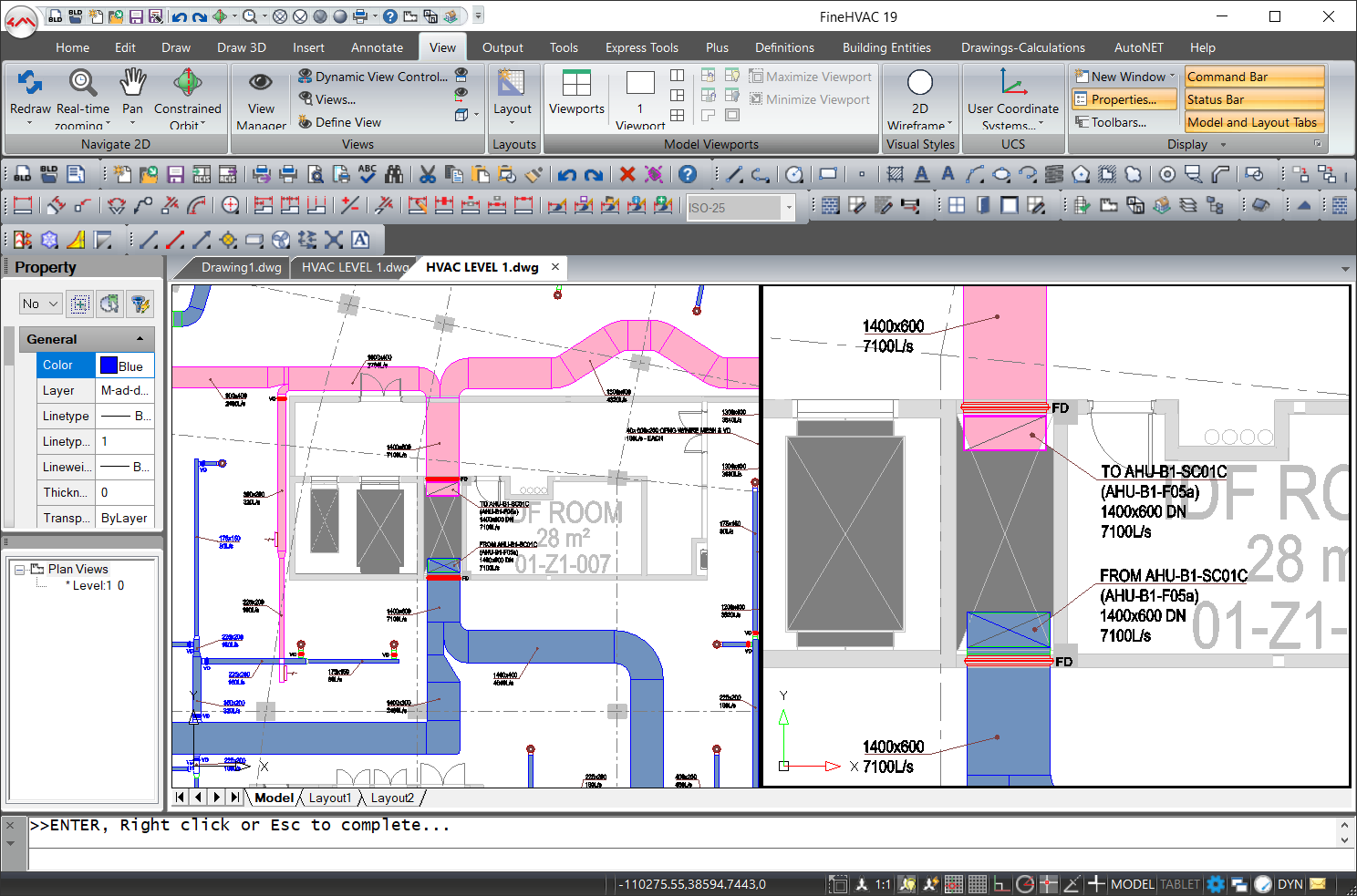

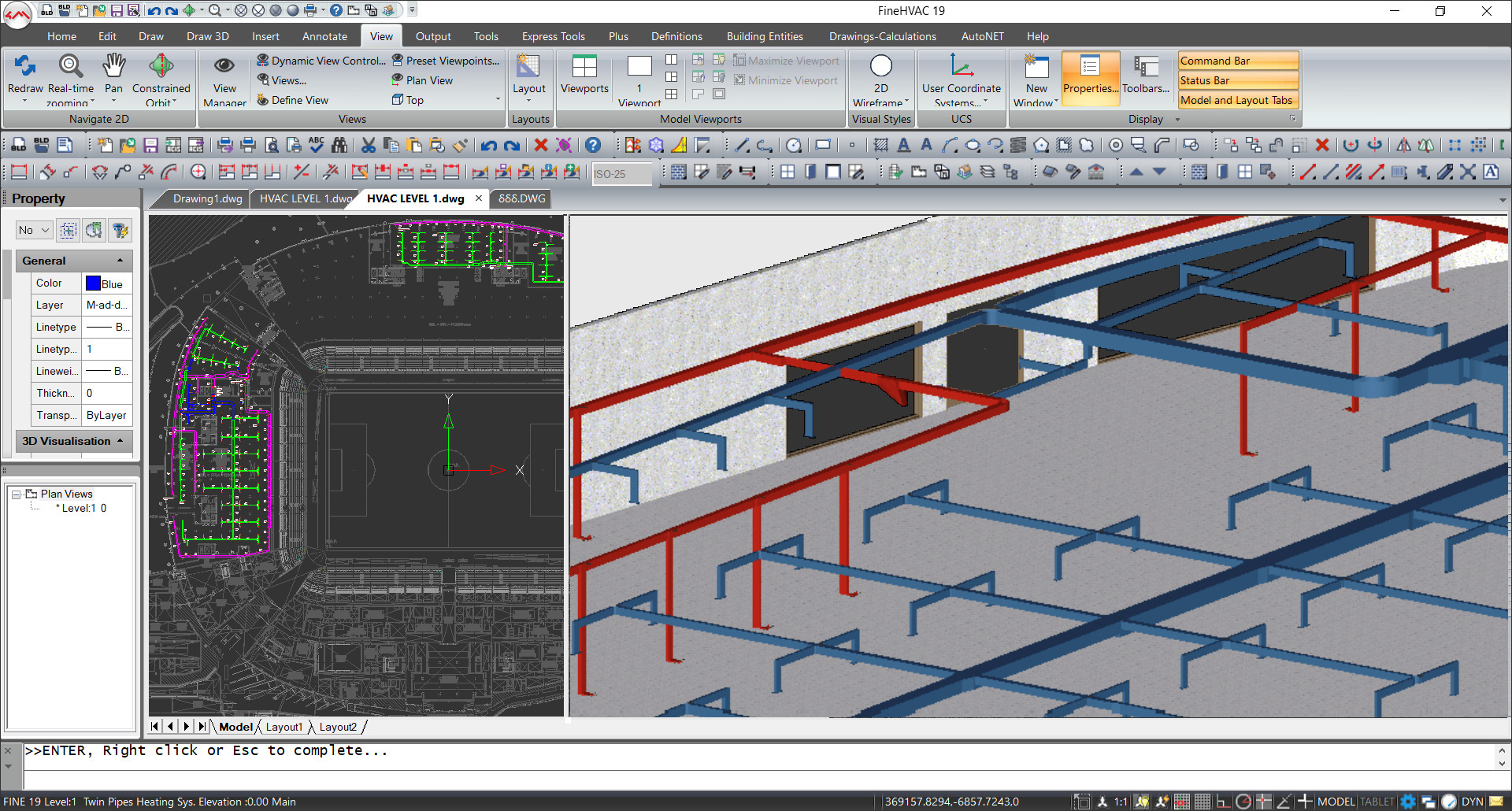

- Easiness and flexibility in creating a piping/air-ducting network model without limits, through a single-line, which, after calculations, is converted to 2D and 3D piping models.

- Smart network modeling in terms of logical recognition of the ΒΙΜ network model (segments/ nodes/ receptors) revealing the numerical values of the network design parameters at every stage of the design process.

- Because of the high visibility and easy control of every pipe segment and/or the entire network, the designer has several options to intervene in order to reach the best design alternatives.

- All network elements (pipes, fittings, grills, fc units, etc.) are objects with their own attributes, easily customized by the user.

User interface

- -No matter its BIM philosophy, FineHVAC has an AutoCAD-like look and feel in order to help the user to design the piping networks faster and easier.

- Further to the DWG compatibility, the program also ensures BIM compatibility with Revit®, Archicad®, Vectorworks®, SketchUp Pro® or equivalent, providing significant file sharing convenience with the other disciplinary team members involved in the project.

- What the user gets after the process is an integrated BIM environment where he/she can work and interact directly on the 3D building model and the HVAC installation model.

Reliability of Results and Documentation

- Long-term use of FineHVAC in a large number of projects according to the international standards (i.e., Ashrae RTS, EN12831, etc.) guarantee reliable calculations.

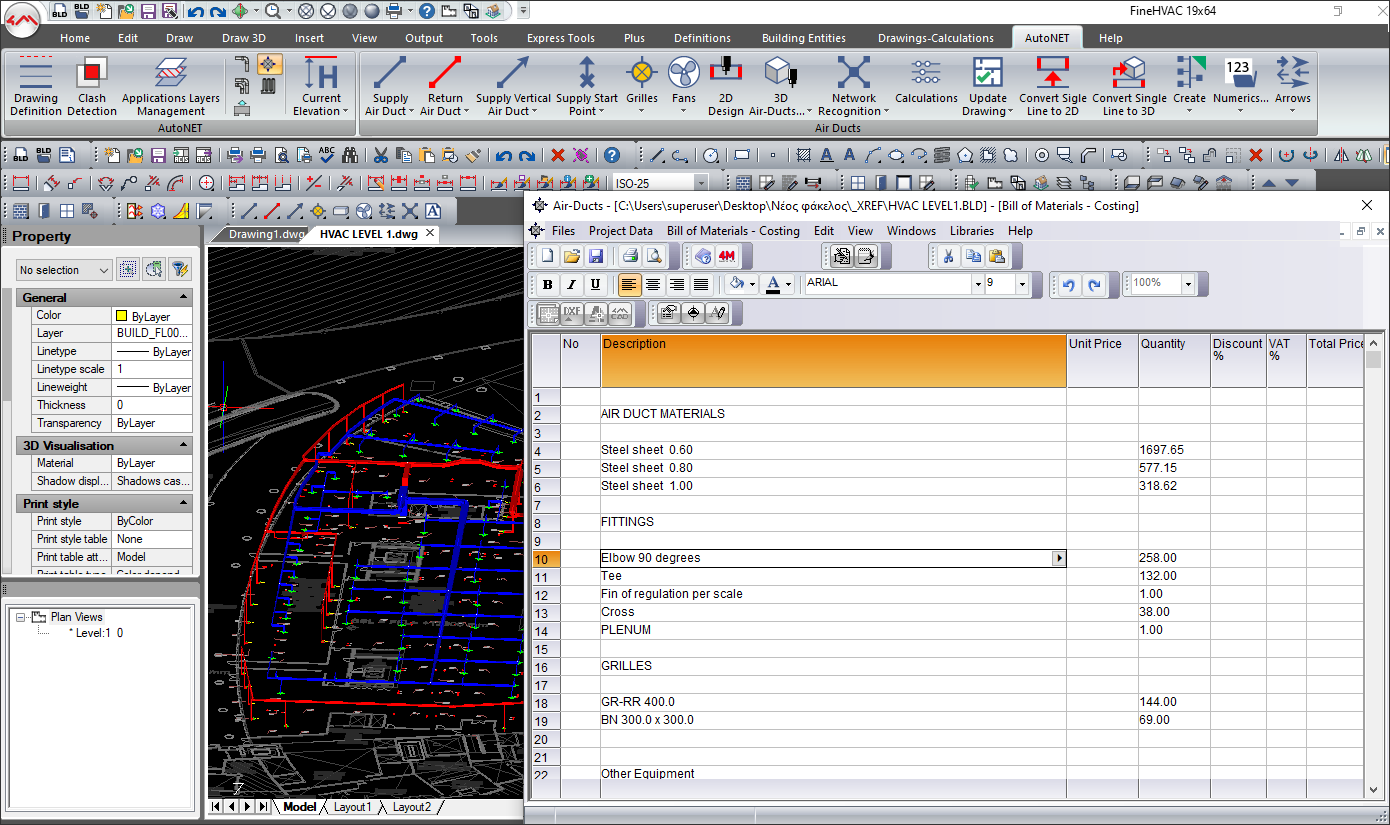

- The exact quantity of the materials that need to be used in the project (i.e., pipe lengths per size, metal sheet dimensions, number of fittings, units, grills, etc.) is automatically generated.

- A fully formatted — following standards — document including both the calculation report with the intermediate and final results, and the complete set of drawings in 2D and 3D can be easily produced. Drawings are automatically updated with the calculation results in detail, while, on the other hand, all this information can be filtered following the user’s preferences, as shown below.

From the program manufacturer’s point of view, the philosophy of FineHVAC is to provide a holistic BIM approach through the synergistic coexistence of drawings and calculation sheets within an integrated BIM environment (Figure 9). This is generally not the case with other BIM solutions, which focus primarily on the creation of the drawings and a rough estimation of the bill of materials. When it comes to the piping sizing and proper selection of the equipment, they rely on being used in combination with third party applications. This makes the whole design process inflexible, more complicated, and time-consuming.

Conclusions

FineHVAC has been used successfully by GKA engineers for the design of the HVAC network installations in the Qatar Foundation Stadium, which will host up to the quarter-finals stage during the FIFA World Cup 2022™.

The program’s ability to handle a wide range of projects of different types and scales is a big plus, but even more important is the flexibility it provides to the user in the smart ΒΙΜ modeling of any HVAC project, which is critical for the automatic generation of the final case study drawings and calculation reports. Equally important is the accuracy in calculations provided by FineHVAC that follow current international standards such as Ashrae, EN, BS and others. In contrast, most other BIM solutions for HVAC and MEP design simply focus on the creation of drawings and tend to rely on third-party applications for the piping, sizing, and proper selection of the equipment.

In conclusion, FineHVAC can support its users to come up with the best design solutions for their project more effectively and efficiently than its competitors.

Company Profile

GKA Engineers was founded in 2011 and focuses on the study and supervision of MEP and Energy Projects in the building and infrastructure areas. Its founding members, Grigoris Drettas El. Engineer, and Kostas Chaniotis, El. & M. Engineer, had already a very long and vast experience in the MEP design with an extensive reference list of projects. Since 2011 GKA has carried out the design of some hundreds of projects in a wide range of fields: Residences, Hotels & Resorts, Healthcare and Social Welfare Buildings, Industrial Facilities and Infrastructures (MEP installations for roads, ports and water supply projects) are some examples. Regarding the energy industry in particular, GKA has designed among others over 150 photovoltaic parks across the globe (Italy, UK, Greece, Brazil, Argentina, Chile, Panama, Bulgaria, Romania and others). The Company's headquarters are located in Athens, 326 Kifisias Avenue.

About the Authors

Grigoris Drettas, El. Eng. and Kostas Chaniotis El. & M. Eng., are founders of GKA Engineers, having four decades of experience in the MEP design.

Nikitas Giannopoulos, M. Eng., is the head of the support department at 4M S.A.

Source: https://aecmag.com