100 percent for climate protection

Biomass-balanced EPS boards from Sto

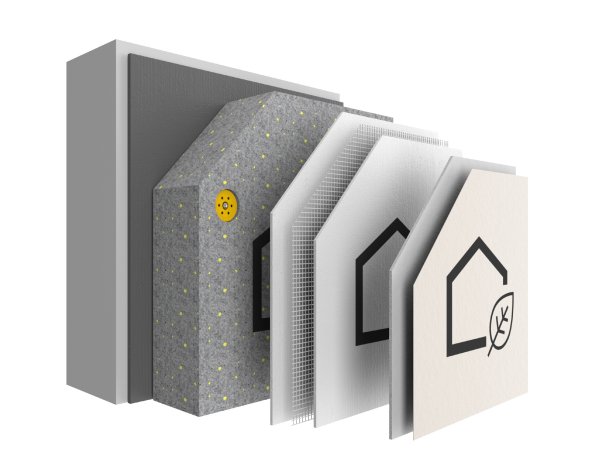

The basic materials of the new Sto insulation board "Top32 Biomass" for facade and interior insulation systems consist of 100 percent renewable raw materials, obtained from organic residues from agriculture and forestry. During production, the certified ecological thermal insulation board causes about two thirds less CO2 emissions than comparable products, which can be claimed in the case of sustainability certifications of buildings. The processing and system properties of the biomass-balanced boards remain unaffected, they are identical to the standard board.

Insulated facades are investments in sustainability because after just one or two years they have saved more energy than was used in their production - and that with a service life of over 60 years. They become even more climate-friendly if the insulating materials are based on renewable raw materials (NawaRo). Just like with the new Sto Top32 Biomass insulation board. 100 percent NawaRos are used to manufacture the raw materials for the certified thermal insulation board made from expanded polystyrene rigid foam in accordance with DIN EN 13163. The independently monitored biomass balance method (BMB) provides proof of this.

Thanks to the ecological raw material basis, the production of the thermal insulation board produces around 66 percent less CO2e (carbon dioxide equivalents) than the production of a comparable fossil-based EPS board. This CO2e reduction can be counted towards all common sustainability certifications for buildings (DGNB, BREEAM, LEED). Just like its fossil counterpart, the eco-certified (REDcert2) thermal insulation board has a thermal conductivity rating of λ 0.032 W/(mK). It is suitable for insulation systems on the facade and in the interior and can be glued or glued and dowelled. It cannot be used in areas in contact with the ground.

Since the panel is made from organic residues from agriculture and forestry using biomass-balanced raw materials, it is environmentally friendly in several ways. Their environmental product declaration clearly shows that BMB products have a significant ecological advantage over conventional materials. Even during their production, they save valuable resources (natural gas and oil) and reduce CO2 emissions. Converted to a single-family house with a facade area of 125 square meters, which is insulated with 20 centimeter thick EPS panels, this saving amounts to around 800 kilograms of CO2e. During their long-term function, the panels save many times over in CO2e due to their effect of reducing building energy consumption.

The new panel based on renewable raw materials corresponds to the usual professional quality in all respects. Apart from its ecological properties, it does not differ from a comparable fossil product. Architects can plan exactly as in the past. Tradesmen get exactly what they know delivered to the construction site, and investors can be sure that the insulation in their building will meet their expectations in terms of durability and value retention.

-------------------------------------------------- -------------------

BOX

What does "biomass balance method" mean?

With the biomass balance method (BMB) certified by REDcert, sustainably produced pre-products can be assigned to a precisely defined use. Since renewable and fossil raw materials are processed in parallel in the large-scale plants of the chemical industry, the BMB organizes the material flows in terms of balance. This rules out misuse and customers can be sure that the exact amount of renewable raw materials required for sustainably manufactured products has actually been used.

Insulated facades are investments in sustainability because after just one or two years they have saved more energy than was used in their production - and that with a service life of over 60 years. They become even more climate-friendly if the insulating materials are based on renewable raw materials (NawaRo). Just like with the new Sto Top32 Biomass insulation board. 100 percent NawaRos are used to manufacture the raw materials for the certified thermal insulation board made from expanded polystyrene rigid foam in accordance with DIN EN 13163. The independently monitored biomass balance method (BMB) provides proof of this.

Thanks to the ecological raw material basis, the production of the thermal insulation board produces around 66 percent less CO2e (carbon dioxide equivalents) than the production of a comparable fossil-based EPS board. This CO2e reduction can be counted towards all common sustainability certifications for buildings (DGNB, BREEAM, LEED). Just like its fossil counterpart, the eco-certified (REDcert2) thermal insulation board has a thermal conductivity rating of λ 0.032 W/(mK). It is suitable for insulation systems on the facade and in the interior and can be glued or glued and dowelled. It cannot be used in areas in contact with the ground.

Since the panel is made from organic residues from agriculture and forestry using biomass-balanced raw materials, it is environmentally friendly in several ways. Their environmental product declaration clearly shows that BMB products have a significant ecological advantage over conventional materials. Even during their production, they save valuable resources (natural gas and oil) and reduce CO2 emissions. Converted to a single-family house with a facade area of 125 square meters, which is insulated with 20 centimeter thick EPS panels, this saving amounts to around 800 kilograms of CO2e. During their long-term function, the panels save many times over in CO2e due to their effect of reducing building energy consumption.

The new panel based on renewable raw materials corresponds to the usual professional quality in all respects. Apart from its ecological properties, it does not differ from a comparable fossil product. Architects can plan exactly as in the past. Tradesmen get exactly what they know delivered to the construction site, and investors can be sure that the insulation in their building will meet their expectations in terms of durability and value retention.

-------------------------------------------------- -------------------

BOX

What does "biomass balance method" mean?

With the biomass balance method (BMB) certified by REDcert, sustainably produced pre-products can be assigned to a precisely defined use. Since renewable and fossil raw materials are processed in parallel in the large-scale plants of the chemical industry, the BMB organizes the material flows in terms of balance. This rules out misuse and customers can be sure that the exact amount of renewable raw materials required for sustainably manufactured products has actually been used.