MIT engineers invent plastic that is stronger than steel

Massachusetts Institute of Technology chemical engineers have invented a new type of plastic that is twice as strong as steel and could one day be used as a building material.

Dubbed 2DPA-1, the material is light and mouldable like plastic but has a strength and resistance that the researchers behind the project liken to steel and bulletproof glass.

The Massachusetts Institute of Technology (MIT) engineers envision 2DPA-1 being used in the near future as a coating to enhance the durability of objects, and eventually as a structural material.

"We don't usually think of plastics as being something that you could use to support a building, but with this material, you can enable new things," said MIT chemical engineering professor Michael Strano. "It has very unusual properties."

Two-dimensional molecular structure gives polymer super-strength

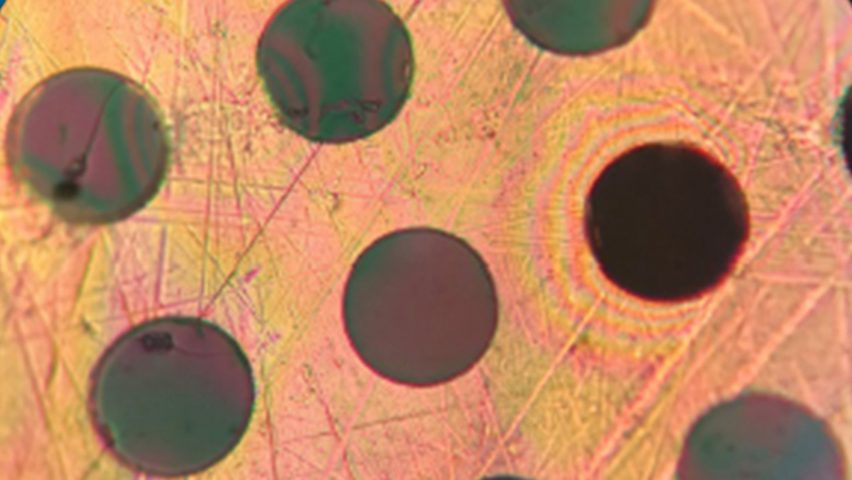

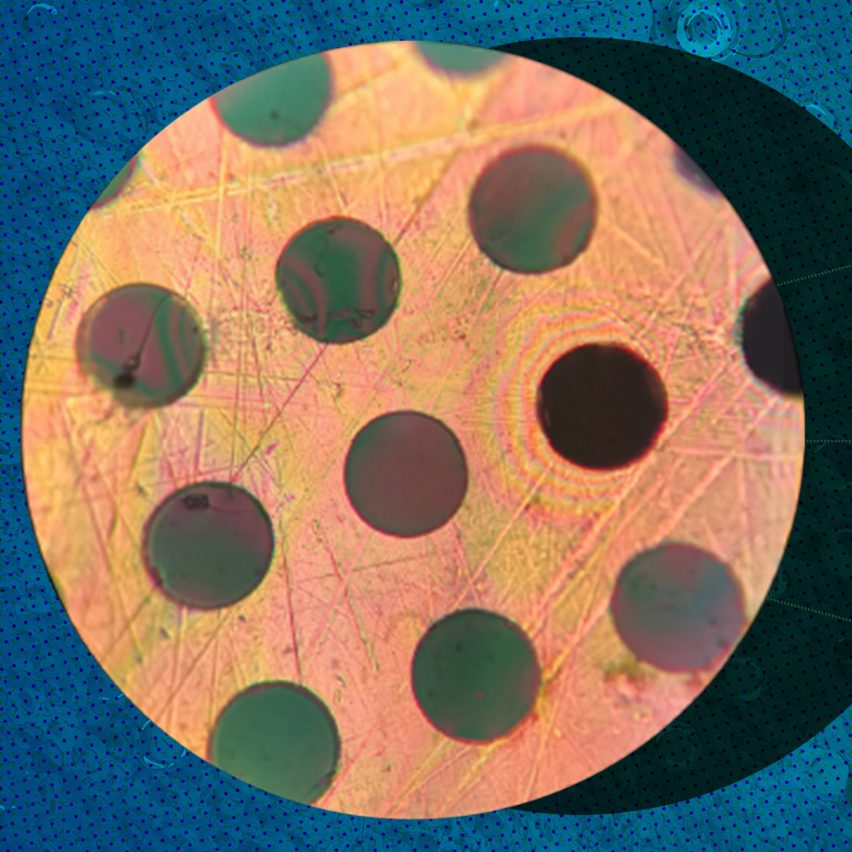

2DPA-1 is a polymer, a category of substance that encompasses all kinds of plastics. But whereas all other polymers grow in one-dimensional chains, with new molecules being added onto their ends, 2DPA-1 grows in two dimensions, forming a sheet called a polyaramide.

"Instead of making a spaghetti-like molecule, we can make a sheet-like molecular plane, where we get molecules to hook themselves together in two dimensions," Strano said.

It's this two-dimensional quality that gives 2DPA-1 its strength, by eliminating the gaps that exist between polymer chains in other plastics.

Its yield strength, or the force it takes to break it, is twice that of steel, although it has only about one-sixth of the material density, making it light.

The researchers also compared it to bulletproof glass, saying it has four to six times the elastic modulus, which refers to the amount of force it takes to deform it.

The engineers synthesised 2DPA-1 using a new polymerisation process that happens spontaneously in the right chemical solution. They have published their findings in a paper in the journal Nature.

Impermeability adds to usefulness of material

The most immediate commercial application for 2DPA-1, according to the researchers, is as an ultrathin barrier coating that could be applied to cars, phones or other objects to make them stronger and more durable.

Because of the material's closed molecular structure compared to other plastics, it is impermeable to water and gases, so it offers an extremely high degree of protection from oxidation, rust or rot.

"This kind of barrier coating could be used to protect metal in cars and other vehicles, or steel structures," said Strano.

However, the future applications for 2DPA-1 extend further, as the molecular sheets can theoretically be stacked to make a building material, or used as nanotubes or nanofibres in a composite material like carbon fibre.

As well as being strong, it has the same appealing properties as other plastics, in that it is light and takes little energy to produce, compared to materials such as steel and glass.

The researchers told Dezeen that they could see it being used as a structural reinforcement material in building and as a separation membrane.

Material can be easily manufactured in large quantities

Another promising quality of 2DPA-1 is that it can be easily made in large quantities.

This means that unlike with some recent wonder materials, such as graphene, it should be easy to scale up manufacturing outside of the laboratory.

The MIT researchers made their 2DPA-1 in beakers, but to make the plastic in large quantities, they say you would simply need to increase the amount of starting materials.

Similar to other plastics, 2DPA-1 is manufactured at room temperature, so it doesn't require vast amounts of heat.

The engineers also theorise that it should be recyclable. If it is used as fibres, it should be able to be re-spun or pulped as with Kevlar fibres, and in other forms it may be able to be chemically recycled as with nylon.

Currently, 79 per cent of plastic is dumped in landfills or in the environment once discarded, where it will remain for thousands of years.

There are numerous different types of plastic currently in existence, as explained in our Dezeen guide to plastic in 2021, as well as a growing number of plastic alternatives.

Source: www.dezeen.com